Hello,

Today id like to share with you some images of the office where i am currently working.

Again all drone images, the above image a little cameo roll as felt that i needed a person in the frame to add some interest.

Have a good weekend.

Lee

Petrofac

Hello,

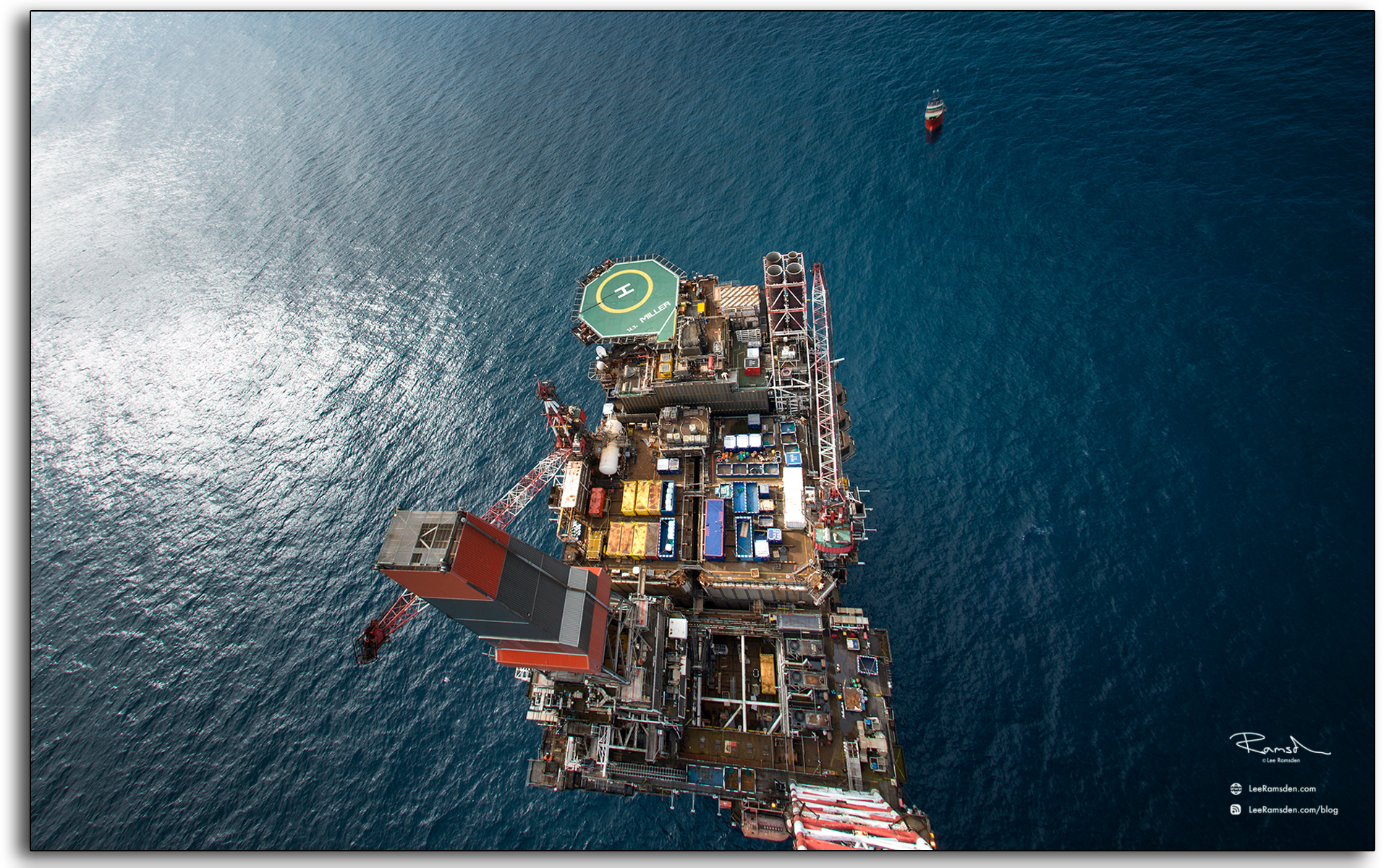

Today id like to share with you some images of the office where i am currently working.

Again all drone images, the above image a little cameo roll as felt that i needed a person in the frame to add some interest.

Have a good weekend.

Lee

Congratulations for Petrofacs Industrial services Rope Access team, for doing an amazing job installing the buildings Christmas decorations :)

Through either a work rotation or weather, i have not physically been home for Christmas day since 2014,

and so just call me Mr Christmas as the Ramsden family are going the whole hog this year.

I hope that you all have a great time, either at home with your families, or if you are stuck at work, hope that you make up for it double when you return.

Thanks

Lee

If you have not yet SUBSCRIBED then please do,

Or head over to instagram and give me a follow

Hello,

Today id like to show, the first couple of lifts.

Above image the rope access riggers, install the cranes lifting equipment.

Once landed the derrick is then sea fastened (welded) to the deck of the S7000.

The next lift to be completed was the helideck.

It was amazing to see these huge bits of an oil rig, look almost insignificant against the huge Saipem S7000 cranes.

Thanks

Hello,

Today id like to show some of the IRATA rope access technicians that were involved in the decommissioning of the BP Miller.

Welding on dead weight supports to the risers.

Rope access welder cutting a riser.

Long tiring climb back up.

Rope techs at height happy in their work.

Hello,

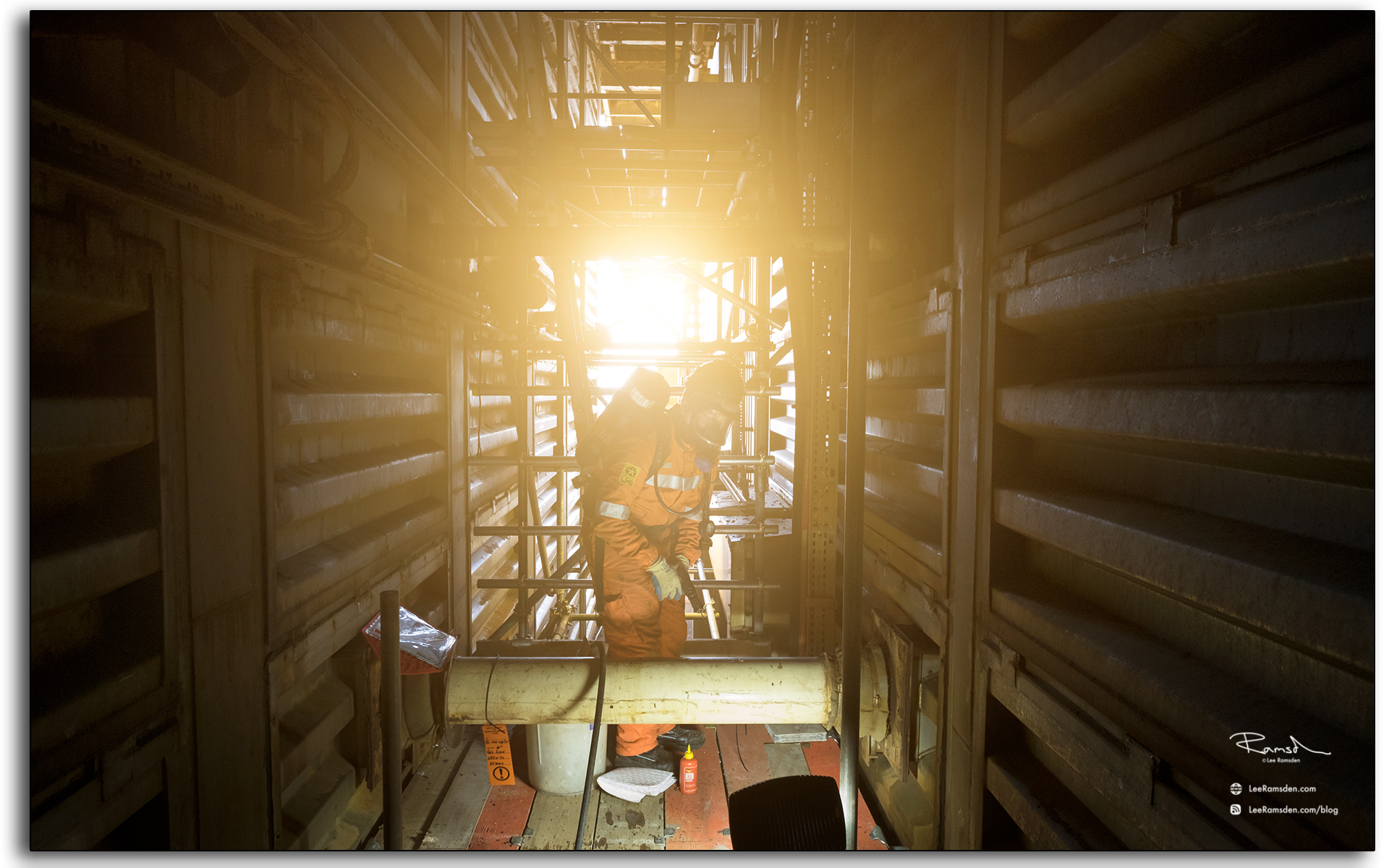

Today id like to show some images of large task involved when safely decommissioning an oil and gas rig. The task is called breaking containment.

Where pipework has to be cut or flanges opened, we have to prove what was inside the pipe work previously, to ensure that it is safe via a gas test.

To prove that the pipe is safe to cut a gas test is required. As the pipework has not yet been proven safe, all this is conducted under full breathing apparatus to protect the technicians drilling into the pipes from hazardous substances.

The offshore scaffolder.

They put up and take down scaffolding that allow offshore workers to reach higher levels during construction, decommissioning, maintenance or cleaning tasks.

In the UK oil and gas industry, it is a requirement for a standby vessel to be present. These vessels primarily cover helicopter operations and if any work has to be conducted where there is a potential to fail to sea. (known as outboard work). These vessels sit there, day in day out, no matter the weather they provide us with emergency cover and would spring to life and help rescue if the unlikely event ever arose.

Today id like to show a few single images. In recent times the Civil aviation has instructed for all UK oil and gas installations to install specific lighting set up on their helidecks, if they require flights in the hours of darkness.

The illuminated helideck against a North Sea sunset makes for quite an interesting image.

Thanks

Lee

Hello,

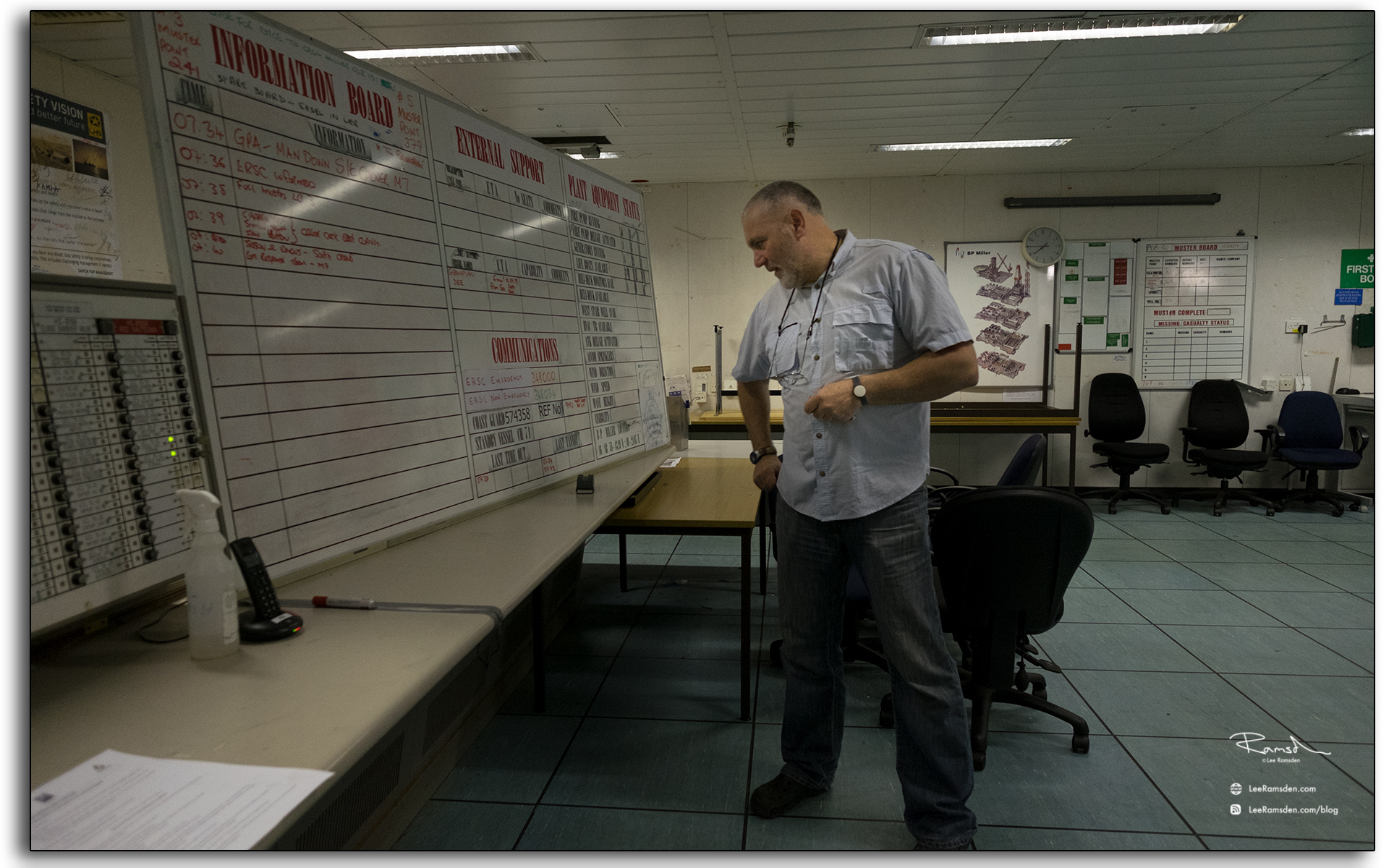

Following on from last weeks post, today we see the Emergency response team practicing if there was an emergency inside the accommodation.

Above is the fire team leader, his role here is directing his fire team, maintaining communications between his team, and the platform control room.

The O.I.M setting the scene, and briefing the emergency fire team.

For exercise - there has been indication of smoke inside the accommodation.

Fire team leader, briefing his team on a suspected accommodation fire indicated on the panel.

Fire team, updating the leader with information.

Fire team, practicing safe fire door drills.

O.I.M and his Deputy, reading through the Emergency response plan.

O.I.M updating the platform personnel, on the situation. The deputy O.I.M calling the coast guard, for exercise purposes informing them of our drill, and establishing helicopter response times.

The scribe, updates relevant information, like wind direction and sea conditions incase we needed to evacuate.

The BP Miller, has the tallest flare stack in the North Sea, at 162m high,

(4m taller than Blackpool tower)

Caught our breath back, after a lung busted 15 ladder climb.

Image of the Brae Bravo platform, from the top of BP Miller flare.

Hello,

Today ill like to show how an oil rig offloads new supplies, which range from equipment, tools and most importantly food!

While it is down to the crane operator to offload the containers from the supply vessel, it is all orchestrated by the offshore materials coordinator.

The materials controller duties:

Arranging for the despatch and delivery of materials and goods

Making sure that materials and equipment have the necessary certification.

Ensuring that relevant stores are aware of deliveries and that they allocate space for goods on arrival.

Chasing up suppliers to ensure goods and materials are delivered on time to meet business needs.

Maintaining the materials management system.

Preparing reports on materials receipt and delivery and on the performance of suppliers

Acting as a focal point for suppliers and internal departments for questions about materials scheduling, problems, and the like.

Norwegian supply vessel crew, unhooking the containers.

Here, are two images 25 years apart.

The images are of the "pig launchers", on the cellar deck of the BP Miller platform,

one while the platform was being commissioned, and put together,

and the second, while decommissioning.

Thanks

Lee

Today we meet, the small team involved in feeding and looking after all 80 workers, on a North Sea oil and gas platform.

These guys do a fantastic job, with such a small team in cleaning, preparing meals and trying to keep moral high for a large crew of guys. Who are working hard in all weathers, away from home for long periods, missing their families.

It is un-measurable their involvement, but any rig worker will tell you, that a clean accommodation and a good hearty meal, makes for a happy crew.

Roast beef, and Yorkshire puddings... must be Sunday!

This fine body of men....

Are one half of the Petrofac core crew involved with the mammoth task of decommissioning and removing a north sea oil rig. While this crew is offshore, our opposite numbers are at home on leave.

This group is made up of the management, technical authorities, and lead technicians, that are required on board to keep a rig running safely.

Petrofac O.I.M.

Petrofac Project Manager.

Petrofac Project Manager.

The above, were the Petrofac offshore management for the project, all with different attributes and experiences, but all shared one key value - people skills.

You can be the most knowledgeable leader, but if your team are not supporting you, then you might as well give up.

These gents led by example, with integrity, and support. When the chips were down, could pick the whole team back up. Inspirational.

Now we called in back to backs and so all the core crew now on board, for the task of shutting down the platform. A mammoth task, completed with safety at the forefront and ahead of the schedule.

The Petrofac O.I.M for the BP Miller decommissioning project.

The Offshore Installation Manager (OIM) is the most senior manager of an offshore platform operating on the UKCS.

Many offshore operators have adopted this UK offshore management model and title and applied it to their operations in all global regions irrespective of the local regulations in force.

In the UK the individual must be officially registered as an OIM with the Offshore Safety Division of the Health and Safety Executive and the OIM is responsible for the health, welfare and safety of the personnel on board the installation, whether a drilling rig, production platform or a support vessel (e.g. a flotel).

Today we had a motivational speaker in work trying to push a poignant message. - Very interesting and what a gent.

In a horrifying workplace accident, Ken Woodward lost his eyesight as well as his sense of taste and smell. It left his family devastated and his colleagues traumatised.

Like all accidents, it could have been prevented. From that moment on he was determined to do all he could to make sure it didn't happen to anyone else.

Since then, his dedication towards creating positive safety cultures and setting new standards has improved the working lives of thousands of people and changed the way hundreds of organisations operate.

Over the last decade he has become a globally recognised figure, providing people with the awareness, mindset and confidence to comfortably approach occupational safety issues with a fresh perspective.

Astonishingly, in one year alone, he made 112 flights, 19 overseas trips and 285 presentations to stop others being hurt.

I strongly recommend booking him, and watch him help you drive the message to your workforce.

Well that was a nice surprise. I logged into the works email system and found out that i had won their Picture competition.

For those of you who don't know, I'm currently sub contracting to a global oil and gas company called Petrofac, as a health and safety advisor. The project is based on the Shetland Isles, building a gas plant.

Over the internal system a few months ago, a photo competition was announced. So i thought that i would have a punt......

turns out my image of Battersea power station was chosen, out of the 5000+ images that were submitted - as the overall winner!!

Over the moon!

A nice new iPad air on route to the house. Thanks ever so much.

The image was displayed on the intranet home page, and globally sent over email to the 10's of thousands of employees world wide.

If there is a plant manager who wants some professional images of their gas/oil plant, some where warm... please speak up. Ha

Thanks

Lee