Hello,

Today, I’d like to share some images taken of some workers on a North Sea asset.

Thanks.

Lee

offshore

Hello,

Today, I’d like to share some images taken of some workers on a North Sea asset.

Thanks.

Lee

Side view of the JB-115 jack-up barge with legs deployed, showing the height and structure above water.

JB-115 is more than just an accommodation jack-up barge; it’s a functional part of offshore life. On boarding, its size, structure, and role become clear — housing, workspaces, crane capacity, and leg height all matter when you’re working miles from land.

The JB-115, owned by JUB, is an MSC SEA-2000 self-elevating unit built in 2009. It houses 64 people with the capacity to increase to 120. Its legs stand 80 meters tall; with a maximum payload of 1,250 tonnes and a 300-ton crane, it handles more than just housing. I captured shots of deck structure, machinery, the legs reaching upward, and the scale of its operations. Whether close-up of welds or distant views of tower and platform, there’s something in the lines, metal, and industrial detail working together.

Platforms like this are where engineering, endurance, and offshore conditions intersect. For more industrial and renewables work, see my Wind Industry and Industrial galleries.

UK offshore wind turbine up close; tower height, blade rotation, scale against sea.

Offshore wind turbines are massive — but how massive? On UK wind farms, turbines can reach up to 204 m to the blade tip, with blade diameters around 164 m. These numbers aren’t just statistics — they shape visual scale, installation requirements, and how turbines integrate into sea and sky.

The turbine in the video above comes from a UK offshore wind farm. At full height of 204 m, the blade tip sweeps an arc almost twice that of many older onshore turbines. For comparison, many onshore turbines are 80-120 m in tip height. That scale affects logistics — transport, foundation design, sea access — and affects what the turbine looks like from shore or sea.

Seeing one in place, through video, gives a real impression of height and movement. The blade diameter of 164 m means each blade is longer than many football fields are wide, and the swept area covers hectares. Height also changes how shadows, wind, and light interact with the structure — tall towers catch more wind, reflect more sky, and tower over waves.

Technical specs like this help understanding what wind turbines are and what they do. For more photographs of UK wind farms, structure and scale, see my Wind Industry and Places galleries.

Good Morning,

Today I’d like to share some images of a substation that I have recently visited.

This is located in the Netherlands side of the North Sea.

I hope that you enjoyed this post,

Have a good week.

Thanks,

Lee

Good morning, I have recently been playing with a 360 camera, here are a couple of stills that i liked from a recent trip offshore.

What do you think about renewable energy?

Share your thoughts in the comments on my instagram @lee_ramsden and explore more of my images to experience the full beauty of offshore wind farms.

Thanks

Lee

Morning,

Here are some images taken on my phone, capturing the transit of personnel from a jack up platform. We were flying in and out of Den Helder in the north of the Netherlands.

Hello, here are some images of the fog slowly creeping in, over the windfarm.

The fog approaches like a soft whisper, gradually swallowing the horizon. The wind turbines, once clear and imposing, begin to fade into the mist, their outlines becoming ghostly silhouettes

The Edda Brint, SOV (service operations vessel) adjacent to our substation.

Housing 60 persons, the 60 PAX will be made up with the ships crew and technicians who are servicing the turbines.

The Wind Cat CTV (crew transfer vessel) This vessel is our daily transport to and from shore.

As the fog thickens, the turbines seem to float in mid-air, their blades slicing through the mist with a gentle, rhythmic motion. This ethereal scene creates a stark contrast between the solid structures and the ephemeral fog.

Have you captured the beauty of fog in your photography? Share your images and comments over on Instagram @lee_ramsden

Thanks

Lee

Hello,

Today I’d like to share a couple of images of an OSP (offshore substation platform)

I always enjoy, how I can take many photos of the same subject, and with the differing skies and ever-changing weather can change the image.

Good morning.

Images of the Wind Orca with a walk to work bridge.

The Wind Orca vessel provides a safe, efficient, and reliable solution for the installation, maintenance, and decommissioning of wind farm projects. Their advanced specifications set the industry benchmark for vessel transit speed, lifting capability, DP station keeping and jacking speed, offering a significantly improved operating weather window. They are fitted with high-quality equipment, supported by advanced preventative maintenance systems, and incorporate a significant level of operating redundancy. Safety is enhanced through a 6-leg design that allows them to operate even on sites with the most challenging seabed conditions.

Let me know what you think of these recent posts I love to hear from you on Instagram @lee_ramsden

Thanks

Lee

Happy Monday.

A couple of images from an offshore work site.

Hello,

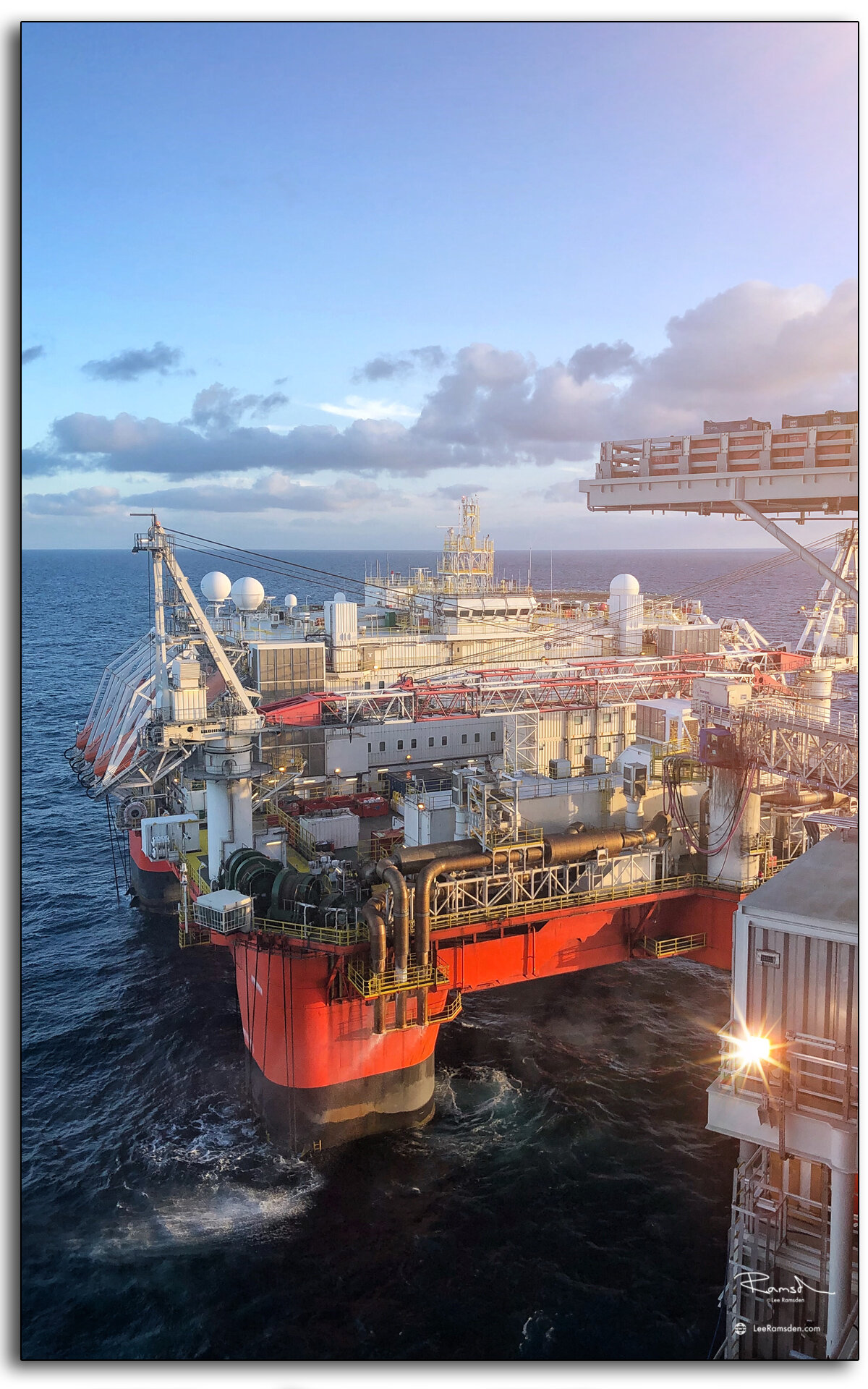

I want to share some images taken of an accommodation vessel..

The Safe Boreas is the most advanced and efficient harsh environment accommodation vessel in the world, constructed to comply with Norwegian regulations.

The vessel has the capacity to accommodate 450 persons in single man cabins.

The layout of the unit is unique, with two large internal atriums allowing natural daylight into cabins, mess room and recreational areas.

The vessel is named after Boreas, the Greek god of the north wind and the bringer of cold winter air.

The name reflects that the vessel is designed for operating in the Norwegian and UK North Sea, a geographical area renown for its cold climate and harsh winters.

The Saipem S7000 arrives.

With its state-of-the-art J-lay tower, upgraded dynamic positioning capability and fast ballasting system, the Saipem 7000 semisubmersible crane vessel has the capacity to handle the entire workscope of offshore construction developments worldwide, encompassing pipelaying in water depths greater than 2,000 metres and heavy lift operations up to 14,000 tonnes.

The vessel’s Class 3 DP system of 12 thrusters ensures that the vessel maintains good station keeping in the most difficult of weather conditions. Additionally, because the Saipem 7000 has accommodation facilities up to 725 people, the vessel can assist hook-up and commissioning as well as initial platform life support activities.

Altogether, this high specification means that the Saipem 7000 can be counted on to provide the highest level of reliability for conventional, deep and ultradeep water development projects.

VESSEL FEATURES

Length overall 197.95 m

Upper platform 175 m x 87 m x 8.5 m

Lower pontoons 165 m x 33 m x 11.25/15.25 m

Depth to main deck 43.5 m

Free deck area 9,000 sq.m

Deck load 15,000 tonnes

Operating draft 27.5 m

Survival draft 18.5 m

Transit draft 10.5 m

Transit speed 9.5 knots

Today I want to show you the last ever flight to the BP Miller oil and gas platform.

Also give you an insight in what happens during a routine Helicopter crew change.

The H.L.O gives permission for a flight to land on the deck.

Offshore worker, happy to be returning to work.

Arriving offshore workers in their survival suits picking up their luggage and leave the helideck.

Bristows Helicopter pilot.

Helideck team get ready the refuelling hose.

A Bristows, Sikorsky S92 Helicopter being refuelled on the oil and gas platform.

Departing offshore worker.

Button her up, time to leave.

As this was the last flight, the pilot was happy to conduct a fly by :)

Hello,

Today id like to show some images of an asbestos inspector conducting a survey of different materials.

Hello,

Today id like to show some of the IRATA rope access technicians that were involved in the decommissioning of the BP Miller.

Welding on dead weight supports to the risers.

Rope access welder cutting a riser.

Long tiring climb back up.

Rope techs at height happy in their work.

Hello,

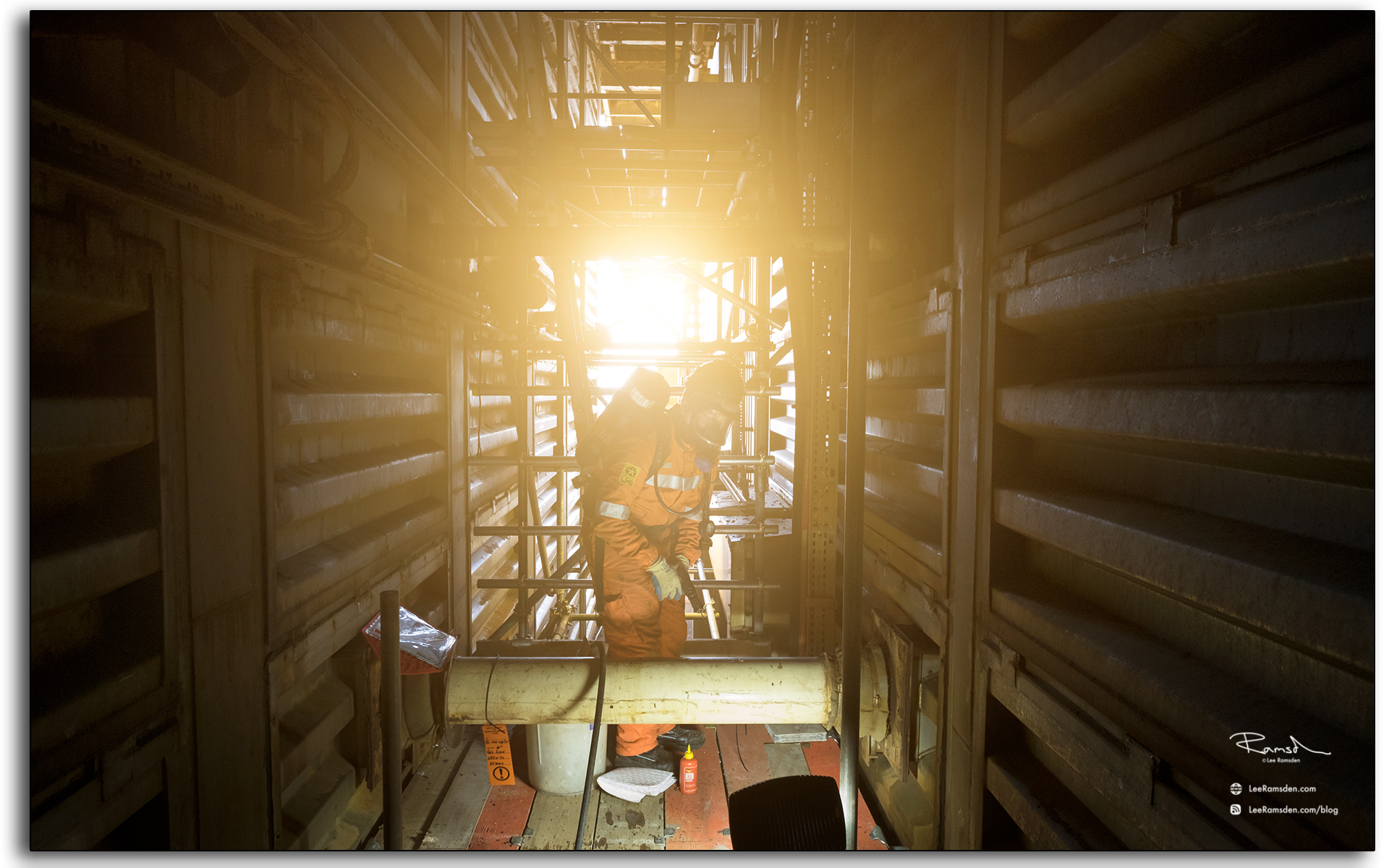

Today id like to show some images of large task involved when safely decommissioning an oil and gas rig. The task is called breaking containment.

Where pipework has to be cut or flanges opened, we have to prove what was inside the pipe work previously, to ensure that it is safe via a gas test.

To prove that the pipe is safe to cut a gas test is required. As the pipework has not yet been proven safe, all this is conducted under full breathing apparatus to protect the technicians drilling into the pipes from hazardous substances.

The offshore scaffolder.

They put up and take down scaffolding that allow offshore workers to reach higher levels during construction, decommissioning, maintenance or cleaning tasks.

Offshore NDT (non-destructive testing) technician. Here he is testing the quality of the welds to ensure that they will not fail when a large load will be applied.

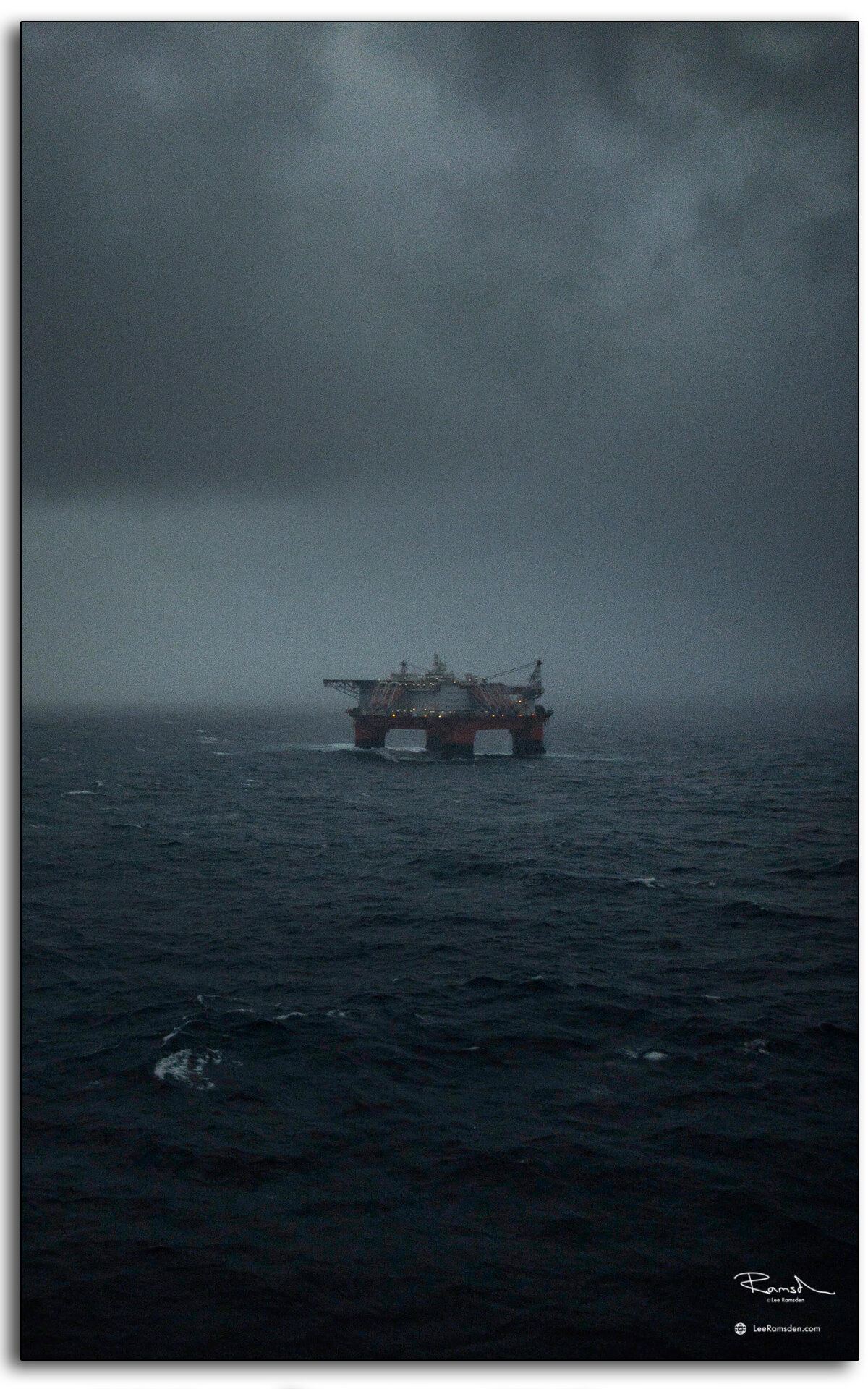

In the UK oil and gas industry, it is a requirement for a standby vessel to be present. These vessels primarily cover helicopter operations and if any work has to be conducted where there is a potential to fail to sea. (known as outboard work). These vessels sit there, day in day out, no matter the weather they provide us with emergency cover and would spring to life and help rescue if the unlikely event ever arose.