The BP Miller, has the tallest flare stack in the North Sea, at 162m high,

(4m taller than Blackpool tower)

Caught our breath back, after a lung busted 15 ladder climb.

Image of the Brae Bravo platform, from the top of BP Miller flare.

The BP Miller, has the tallest flare stack in the North Sea, at 162m high,

(4m taller than Blackpool tower)

Caught our breath back, after a lung busted 15 ladder climb.

Image of the Brae Bravo platform, from the top of BP Miller flare.

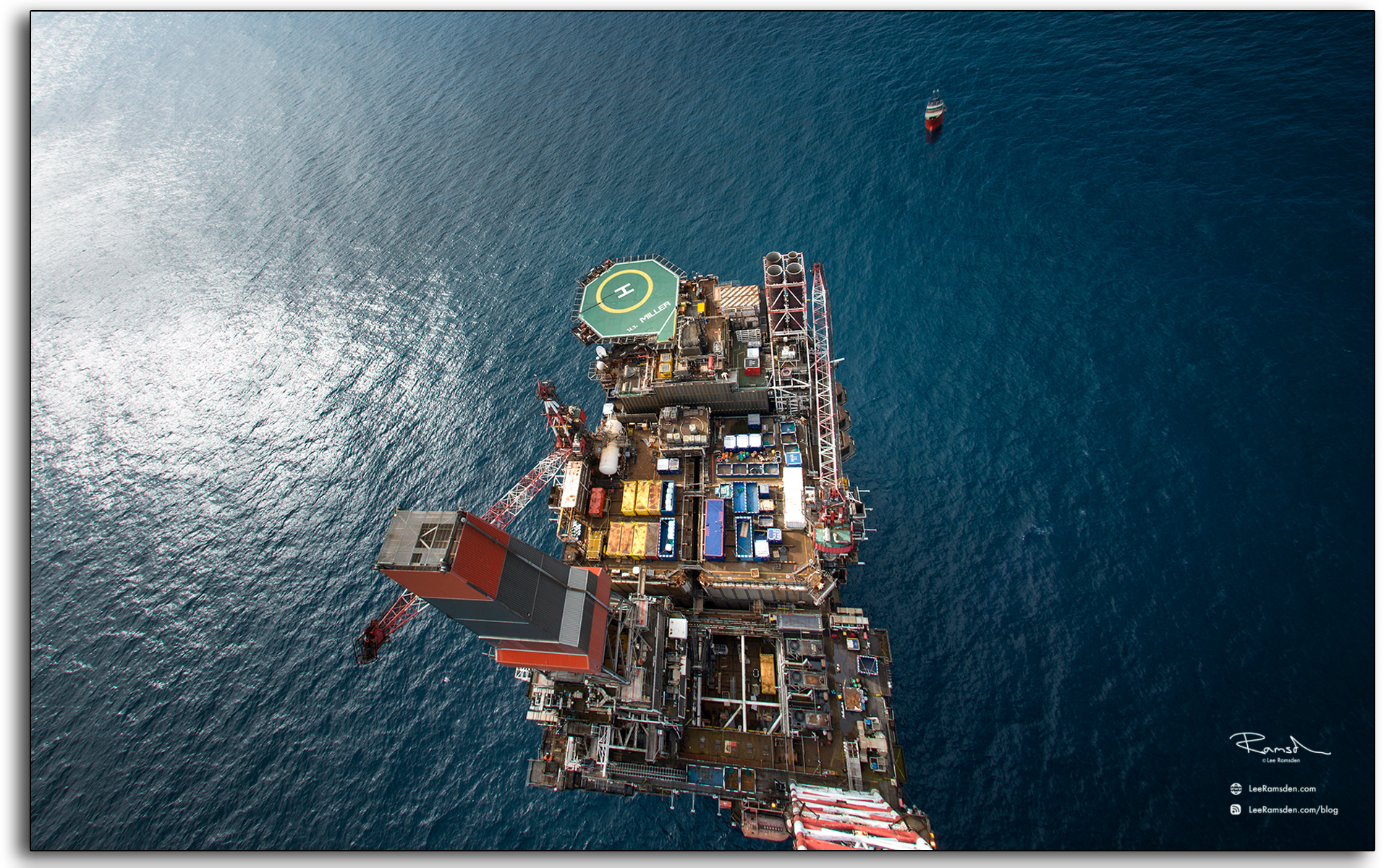

Hello,

Today ill like to show how an oil rig offloads new supplies, which range from equipment, tools and most importantly food!

While it is down to the crane operator to offload the containers from the supply vessel, it is all orchestrated by the offshore materials coordinator.

The materials controller duties:

Arranging for the despatch and delivery of materials and goods

Making sure that materials and equipment have the necessary certification.

Ensuring that relevant stores are aware of deliveries and that they allocate space for goods on arrival.

Chasing up suppliers to ensure goods and materials are delivered on time to meet business needs.

Maintaining the materials management system.

Preparing reports on materials receipt and delivery and on the performance of suppliers

Acting as a focal point for suppliers and internal departments for questions about materials scheduling, problems, and the like.

Norwegian supply vessel crew, unhooking the containers.

Here, are two images 25 years apart.

The images are of the "pig launchers", on the cellar deck of the BP Miller platform,

one while the platform was being commissioned, and put together,

and the second, while decommissioning.

Thanks

Lee

Today we meet, the small team involved in feeding and looking after all 80 workers, on a North Sea oil and gas platform.

These guys do a fantastic job, with such a small team in cleaning, preparing meals and trying to keep moral high for a large crew of guys. Who are working hard in all weathers, away from home for long periods, missing their families.

It is un-measurable their involvement, but any rig worker will tell you, that a clean accommodation and a good hearty meal, makes for a happy crew.

Roast beef, and Yorkshire puddings... must be Sunday!

This fine body of men....

Are one half of the Petrofac core crew involved with the mammoth task of decommissioning and removing a north sea oil rig. While this crew is offshore, our opposite numbers are at home on leave.

This group is made up of the management, technical authorities, and lead technicians, that are required on board to keep a rig running safely.

Petrofac O.I.M.

Petrofac Project Manager.

Petrofac Project Manager.

The above, were the Petrofac offshore management for the project, all with different attributes and experiences, but all shared one key value - people skills.

You can be the most knowledgeable leader, but if your team are not supporting you, then you might as well give up.

These gents led by example, with integrity, and support. When the chips were down, could pick the whole team back up. Inspirational.

Now we called in back to backs and so all the core crew now on board, for the task of shutting down the platform. A mammoth task, completed with safety at the forefront and ahead of the schedule.

The Petrofac O.I.M for the BP Miller decommissioning project.

The Offshore Installation Manager (OIM) is the most senior manager of an offshore platform operating on the UKCS.

Many offshore operators have adopted this UK offshore management model and title and applied it to their operations in all global regions irrespective of the local regulations in force.

In the UK the individual must be officially registered as an OIM with the Offshore Safety Division of the Health and Safety Executive and the OIM is responsible for the health, welfare and safety of the personnel on board the installation, whether a drilling rig, production platform or a support vessel (e.g. a flotel).

Well... Hello, its been a while.

Lets catch up,

Most will know, that my day job is working in the oil and gas industry.

Since January i have been involved with the decommissioning of a north sea oil and gas rig, called the BP Miller.

The picture taking had to take a back seat. The next post will explain in more detail what the project entails.

But stick around, i have uploaded lots of content which will be coming out on a weekly basis, a new post every Sunday.

So please subscribe, and follow the story and images of life offshore in the oil and gas industry on a decommissioning project.

Thanks

Lee

Good Morning,

As most are aware with my day job, i spend half my life at airports traveling. And so this time i brought my little Fuji X-T1 along for a ride, and took some shots while i was awaiting to board the plane.

Thanks

Lee

Hi,

just a quick one as i am sure a lot of you are more experienced with this than myself.

Whilst traveling to work i was taking some pictures on the flight. To avoid the cabin crew scowl i turned the Fuji X-T1's shutter from Mechanical to electronic.

It is permanently set on the Mechanic mode, as in the past, i accidentally put it onto electronic and it would not fire the off camera flashes. To prevent that happening again, it is a setting i do not change.

This occasion due to the silence of the electronic shutter, it would be a perfect solution.

Just for a demonstration and comparison, as i didn't want to take pictures of the planes propellers.

Have a look at the two images. The top image is the conventional mechanical shutter. And the lower is the electronic. I found it really interesting how the shutters create different images.

Thanks

Blackpool football club Bloomfield road.

Hi following on from my last post. I thought i would share some images taken from the top of Blackpool tower.

Pleasure beach.

Winter Gardens Theatre.

Funny Girls burlesque cabaret showbar.

Roof tops.

Lancashire Ambulance service.

A towns taxi cab.

Offices.

Lytham road B5262.

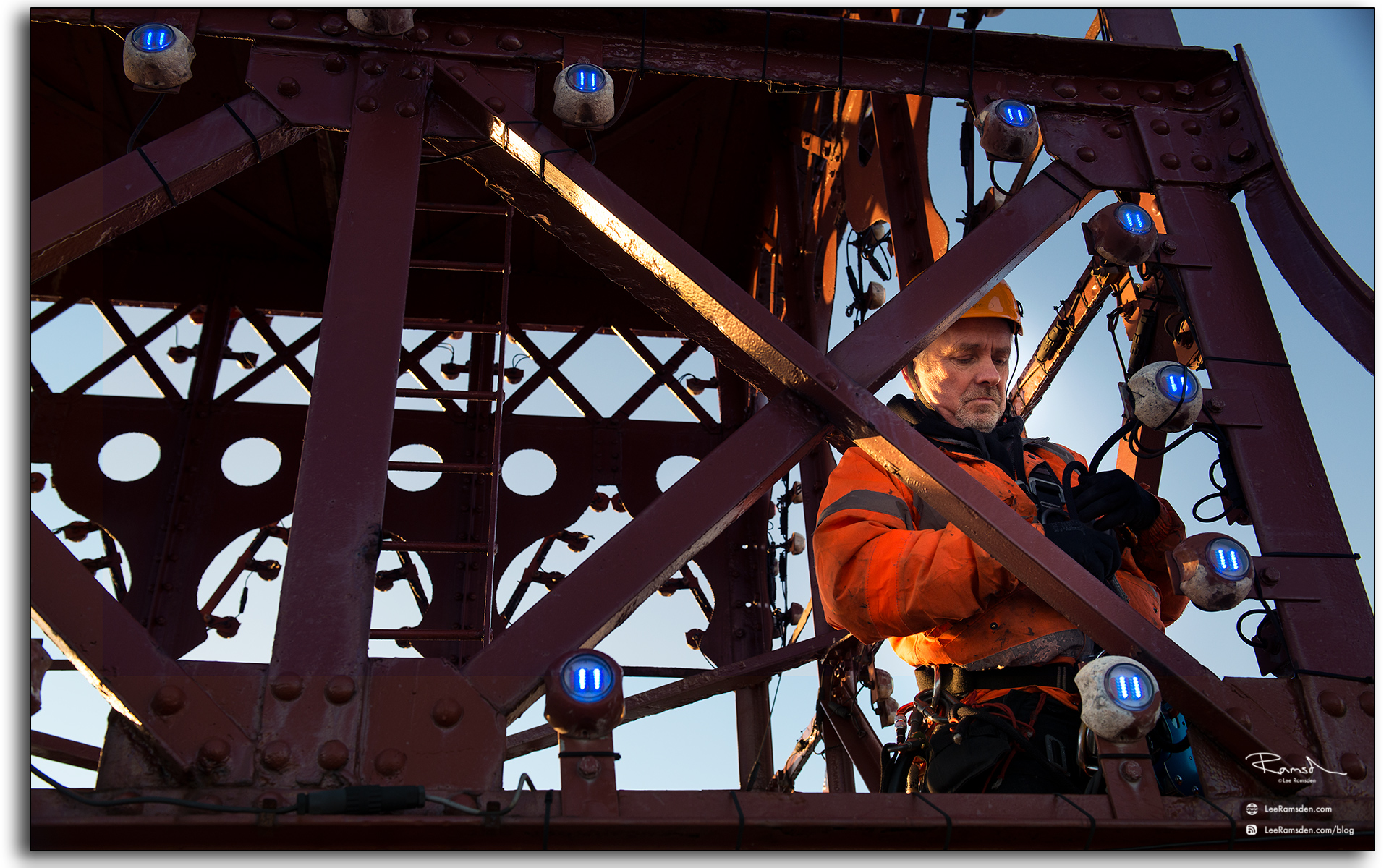

Have you ever wondered, - how do they maintain the iconic lights on Blackpool Tower?

Well meet Wez Berry, the lighting engineer that looks after the famous Blackpool Tower and regularly abseils 518 ft down the iconic landmark, to ensure its computer-operated 225,000 LED bulbs are in working order.

The day starts early to catch the lift to the top.

Wez's workplace has a view like no other.

“You're your own boss up here, You can crack on and do your own work.”

The location is extremely weather dependent, with extreme winds and rain meaning it simply isn't safe to scale the Tower's dizzy heights.

“If the weather's nice, we're on, and I'll work through weekends and bank holidays,”

“The wind really does restrict us and you have to look at the forecast very carefully."

“You've got to come into work safe and go home safe – it's very much safety first and I always have a rope access supervisor in case anything happens to me up there."

"We work closely with CJIS-LTD who provide the highly trained rope access supervisors who manage the working at height, utilising IRATA techniques"

Wez -"we're working off 100 metre ropes. It doesn't scare me because whether its 20 feet or 500 feet there's no messing about and you've got to give it the same respect.”

Even when the lighting engineer is at home, he can see the Tower from his back window and he'll often get a call from work mates asking him to check on the lights.

“Plus everyone round here knows what I do, they love to criticise and tell me if they see a light out,”.

The tallest light fitting in Lancashire.

The top is a mecca for tourists, who flock to the terrifying glass floor known as the SkyWalk. Often, they will catch a glimpse of Wez hanging underneath.

To illustrate just how high todays worksite was.

For more information on how to conduct working at height safely please use the contacts page.

If you are or interested in becoming a rope access technician or require additional training i can recommend this training venue Based in Blackpool.

Thanks

Lee

Good morning, A few images from a recent wedding.

Congratulations Maia and Martin.

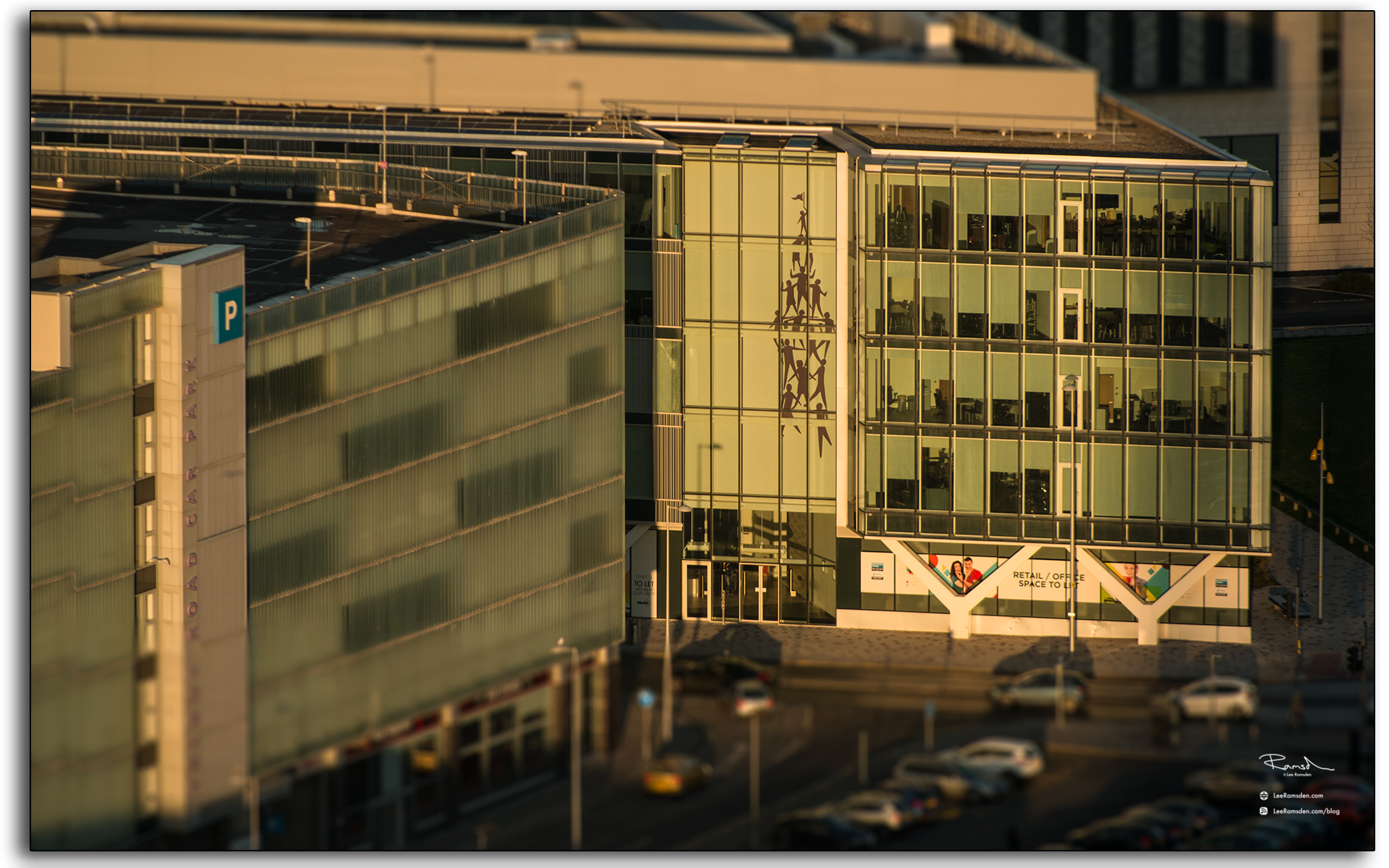

Good morning, i hope that you are well.

Today i'd like to share a quick thought on how you can use image stitching to over come problems.

I appreciate that this is nothing new, but with some fore-thought it can become a powerful tool in your arsenal.

I was commissioned to shoot an office building. The front had no access due to very limited space and parked cars in my way. Even with the lens at 24mm it was simply impossible to fit the building into frame. So stitching is the only way forward.

The above image was created with around 25 images.

Here you can see the images used,

the camera was mounted on a tripod and i systematically panned left to right making sure to over lap alot. The building took 3 passes.

Always best to have more frames than needed, than have pieces missing down the line.

With each up date of Photoshop CC i have noticed that it is becoming much better at stitching.

In the past it would have not been able to do this, and for these cases i use Autopano Giga 3.0 stitching software, but photoshop managed ok with this.

Now by using a tilt shift lens, and/or a parallax tripod head, your job in post will be so much easier, but as i do not own either of these i had to make do. The majority of my time was spent straightening the stitched image.

As with all panos, shoot in manual, turn white balance off auto so all the images remain consistent.

I hope that this helps, and when you are trying to shoot a subject larger than your frame, that you remember this technique.

Thanks

Lee

Nikon D800 f7.1 1/8th ISO100

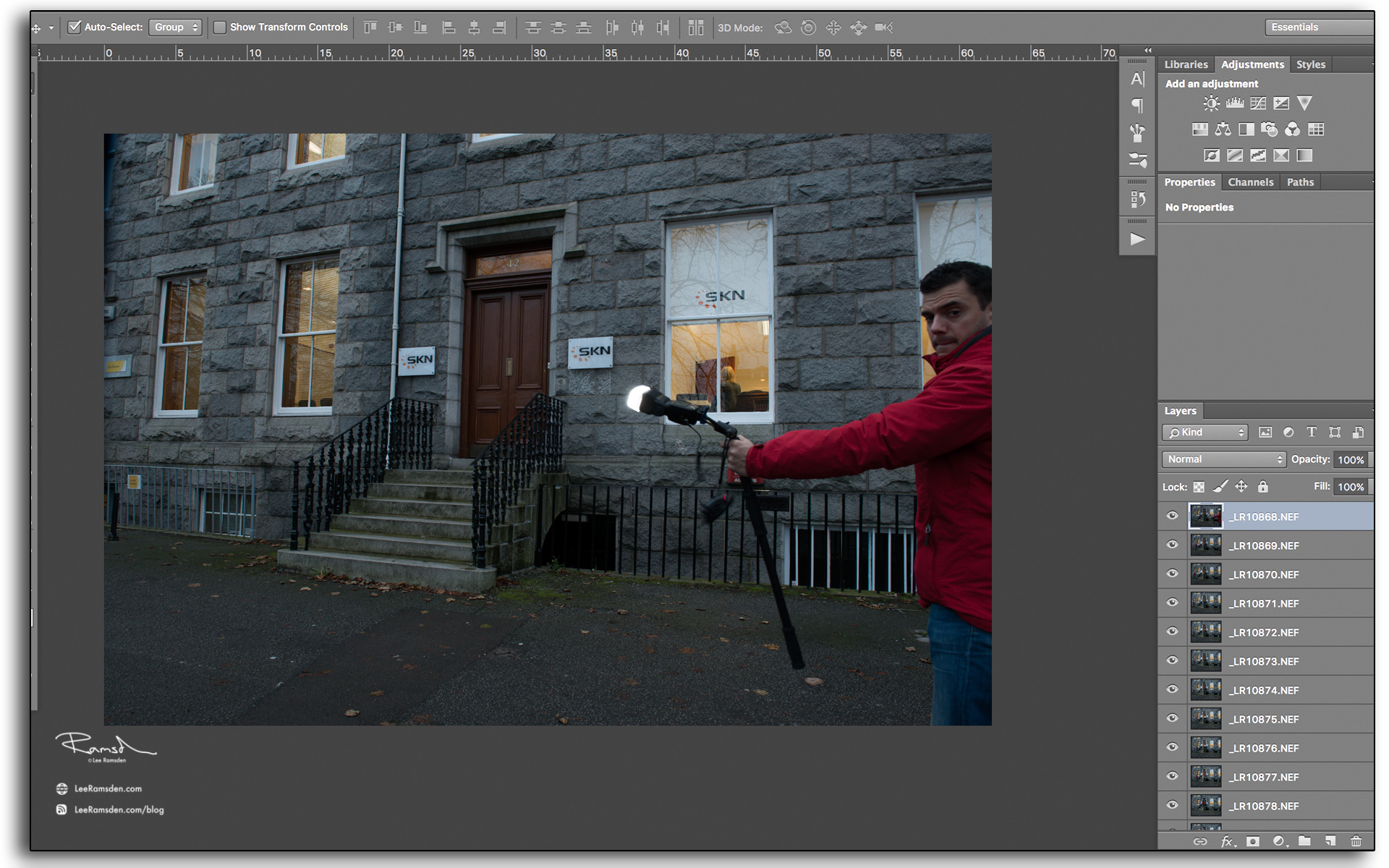

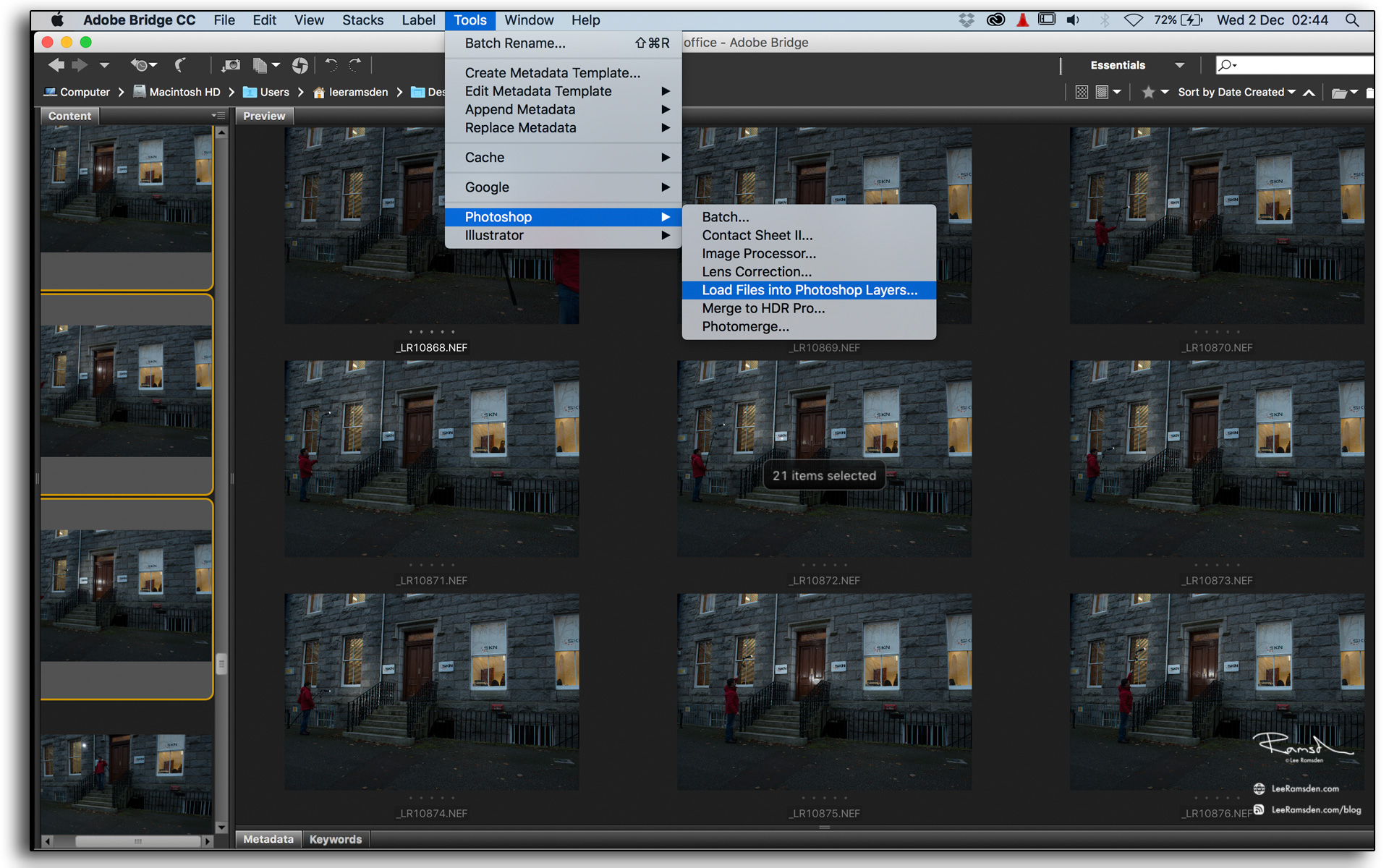

Good morning,

Id like to share with you a lighting technique that you can use to light a scene, even when working on your own.

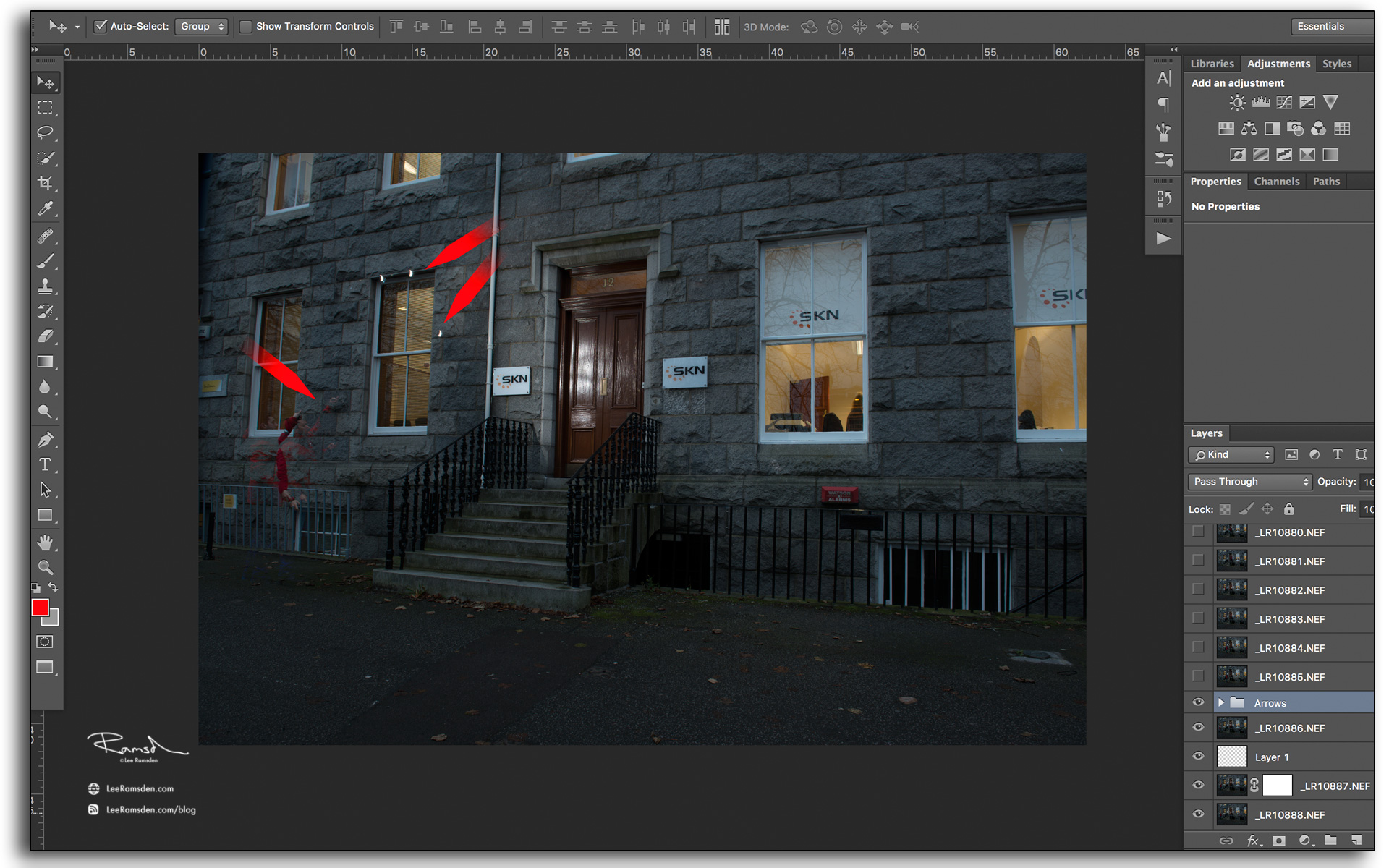

The above image consists of 21 images, all shot and lit by myself, and i am even in the image, to add some interest.

I will show you, how i take multiple images, all lit with off camera flash, and then the process i take in photoshop.

Here you can see me using an off camera flash head on a pole, with the trigger in my right hand firing off the flash and camera shutter remotely.

Click on image to enlarge.

The final image is composed of 21 frames.

The camera was mounted on a tripod. White balance taken off auto, manual settings, and with me using back button focusing on the camera, i know when i press the remote, the camera will not try and focus, making all the images consistent.

Quick tip,

Like when making panos, my first image is a large image of me, so i can find the set easily in bridge.

Also this is a great way to make sure that the flash and camera shutter both fire correctly.

As when using pocket wizards as the remote, the flash PW has to be set to a channel higher and some times i forget this, and so it is always a good idea to test everything before getting started and walking far into the scene.

Using bridge i select all the images that i want to use, and from here you can easily load them into photoshop as a single document with 21 layers.

Now turn off all layers, and starting from the bottom layer i work my way up through the stack, turning on, one layer at a time, changing the blend mode to Lighten.

With the blend mode on lighten, the flash light will show.

Also you will see indicated in this image the hot spot of the flash is in the image. This is easy to mask out. Also i remain in the image by some strange artefacts, just simply mask these out.

After some cleaning and tweaking here is the before and after image.

The before being unlit.

It is a subtle difference, but one i find takes your images to that next level.

If you have any questions, feel free to comment and i hope to help.

Thanks

Lee

Fuji X-T1 F4 1/125 ISO1600

A few images taken from a recent trip offshore on the Talisman Auk platform in the North sea.

Fuji X-T1 F7.1 1/125 ISO1600

Fuji XT-1 F5.0 1/125 ISO1600

Fuji X-T1 F1.8 1/125 ISO1600

Fuji X-T1 F1.8 ISO1600

Fuji X-T1 F1.4 1/125 ISO1600

Fuji film X-T1 f4 1/180 ISO400

Morning,

Following last weeks post, i thought id share a couple more images from my time on the Talisman AUK oil and gas rig in the north sea.

Fuji film X-T1 f8 1/180 ISO200

Drilling rig in the distance.

Fuji film X-T1 f10 1/80 ISO1000

Fuji film X-T1 f2 1/80 ISO1000

Electrical inspection of the fire and gas system.

Fuji film X-T1 f2 1/80 ISO1000

Fuji film X-T1 f2.8 1/125 ISO1250

Fuji film X-T1 f3.2 1/30 ISO1250

Fuji film X-T1 f2.8 1/125 ISO1250

If you have enjoyed these oil and gas industry images,

Please feel free to share these posts on your social media, giving credit to the photographer Lee Ramsden @ www.leeramsden.com

Many Thanks

The Auk Oilfield is situated 249 kilometres (155 mi) east, southeast of Aberdeen, Scotland. It was operated by Shell UK in 50% partnership with ESSO until October 2006 when it was bought by Talisman Energy, and is now licensed by Talisman Energy. It was discovered in October 1970 in a water depth of 182 metres.

Drawing courtesy of google images

Production started in December 1975 from the Auk 'A' platform. This platform is a steel, 8 legged jacket designed by Shell Oil and constructed at Methyl Fife Scotland. This jacket weighs 3,414 tonnes and support a topside weight of around 8,000 tonnes.

Fuji film X-T1 f3.2 1/125 ISO200

Helicopter Departures.

Fuji film X-T1 f5.6 1/125 ISO200

Our transport to the platform, ready for action.

Fuji film X-T1 f2.8 1/125 ISO800

For me to be able to take picture offshore, it is well controlled. Permit to work, and gas tests are required.

Fuji film X-T1 f3.2 1/60 ISO800

Flaring off excess gas.

Fuji film X-T1 f3.6 1/60 ISO800

Our office, where the magic happens.

Fuji film X-T1 f2.8 1/60 ISO800

Technician climbing to his work front. We use IRATA - industrial rope access techniques and procedures to work at height safely.

Fuji film X-T1 f1.6 1/60 ISO800

SKN electrical technician.

Fuji film X-T1 f1.6 1/80 ISO800

Electrical inspections being carried out.

Fuji film X-T1 f4 1/60 ISO800

After all that climbing, a cup of tea is required.

Fuji film X-T1 f2.8 1/60 ISO800

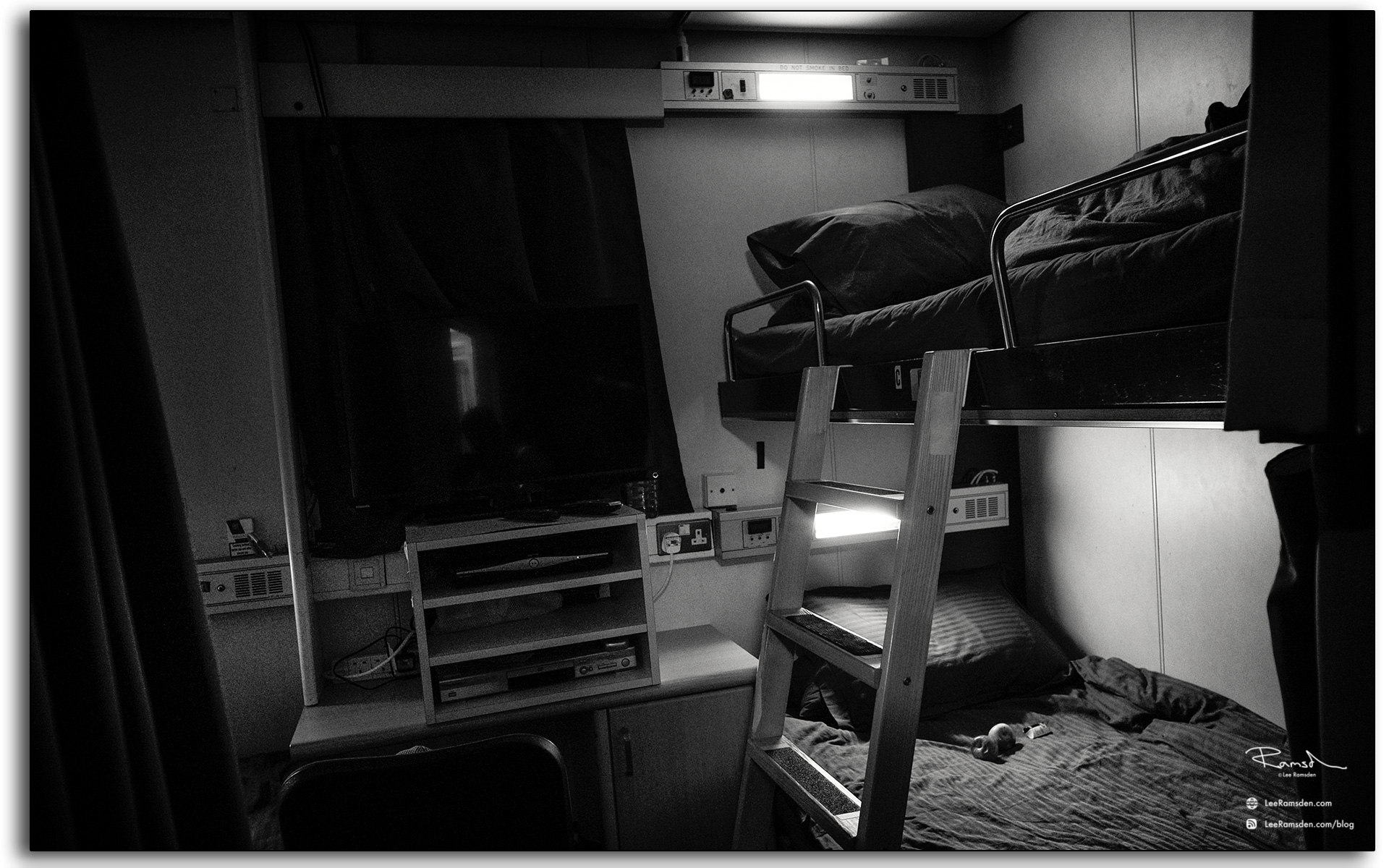

Off shift movie time.

Fuji film X-T1 f2.8 1/60 ISO1250

40 year old ensuite rooms.

Fuji film X-T1 f3.2 1/60 ISO1250

Bunks fit for a king.

A fact which i found funny - The field is named after the Auk a family of sea birds. There is a legend that it was to be called A UK, as the first British oilfield, until somebody realised that the sixth field would be called F UK and Shell's policy was rapidly changed to name their fields after sea birds. Shells sixth UK oilfield is called Fulmar.

Please feel free to share this post on your social media, giving credit to the photographer Lee Ramsden www.leeramsden.com

Thanks